Capabilities

Pre-Met Ltd is a worldwide precision engineering supplier & manufacturer of metal pressings and stampings. Customers receive comprehensive support for all stages from concept to product approval and validation.

Concept & Design

Unique design solutions and high quality materials for the most challenging of technical issues. Our highly trained and knowledgeable workforce have the practical design experience to deliver optimal results for your project. Pre-Met can support your project at any stage delivering efficiency and high standards of manufacturing using the latest CAD, CAM and Solid Works systems.

Tooling

With an onsite, fully equipped tool room for manufacturing most production tools to support our design and production, Pre-Met has the capability to manufacture a wide diversity of products. From simple, low cost, single impression tooling to more complex progression tooling. Catering for all requirements and budgets. Also, tool servicing and maintenance for the whole of a project life cycle.

Prototyping

Pre-Met has a full suite of cutting edge prototyping capabilities and

pre-production facilities for after the design stage. Also, a low volume section which is fully equipped to create prototypes before pre-production and full-scale production commences.

Quality

Pre-Met Ltd is dedicated to supplying high quality products, robust project management and exceptional customer service. Quality is guaranteed with consistent compliance to our Quality Management Systems and EMS systems. Pre-Met has excellent relationships with our Customer and Supply Base, which ensures high standards of delivery across the supply chain. We always strive to meet and exceed specifications to provide the best services possible, and remain compliant to industry regulations and standards.

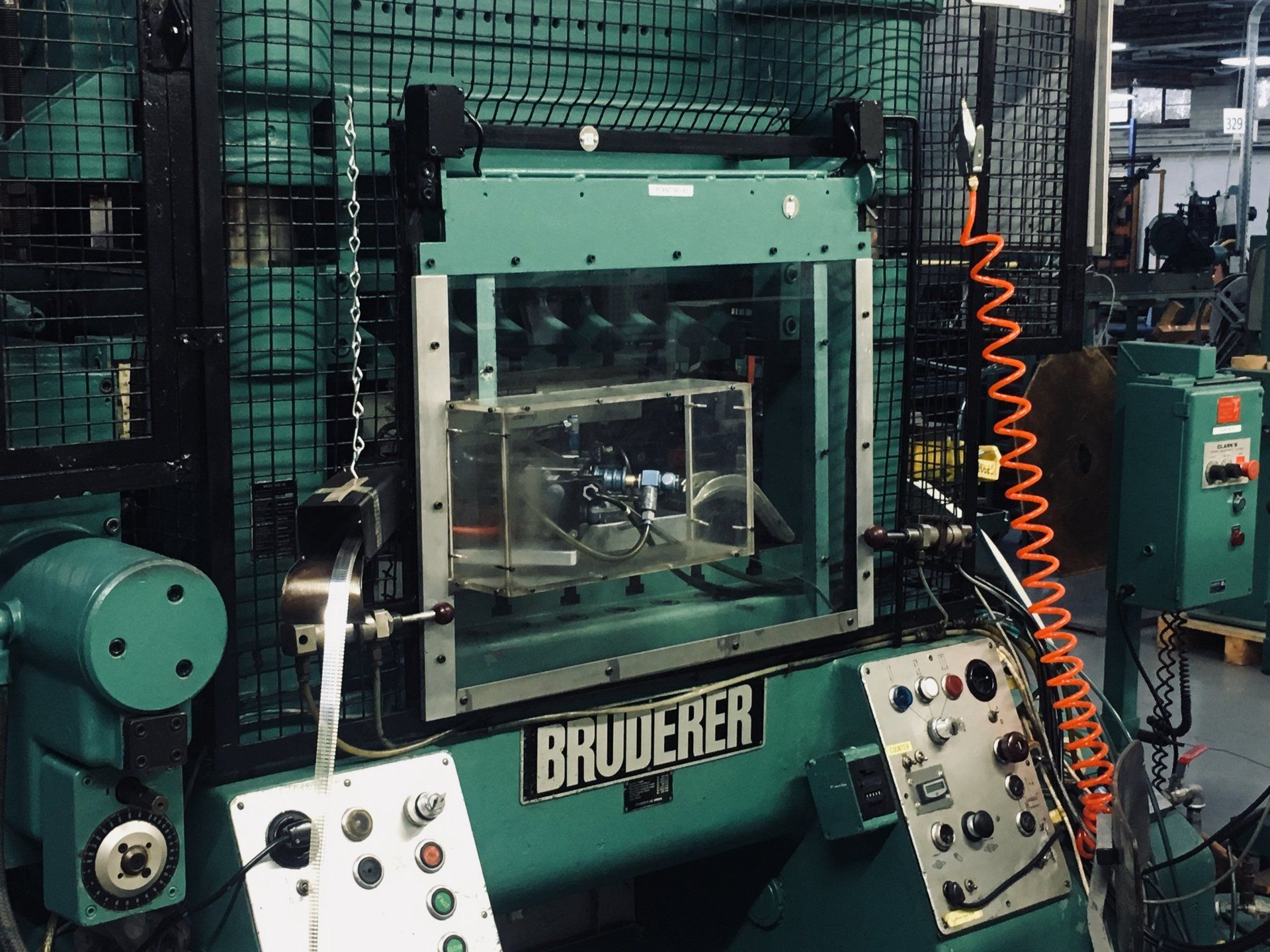

Production

Pre-Met can manufacture products and components for a variety of sizes, complexities and volumes. 70 presses from hydraulic, 25 tonne and extended bed CP2 tonne Yangli press and a low volume production area with hand presses. Other machines include Bihler, Finzer and Heenan & Froude multi-slide presses plus SMV presses for specialist operations.

Finishing

Pre-Met has a comprehensive range of finishing including assembly and sub-assembly, welding, riveting and rapid insertion of metallic components into plastic moulding. Also, designing and building fully automatic assembly equipment .

A range of welding including high speed computer operated and seam welding for high volume projects. For small batch work there is stand alone welding and riveting equipment. Heat treatment finishes and a range of plating and coating finishes are also available.

Inspection

Pre-Met monitors production during each manufacturing stage using a range of advanced equipment. This includes OGP, non-contact, optical measuring machines, OGP non-contact optical measuring machines, shadowgraphs with automatic edge detection and hand held measuring instruments. SPC data is collected during the optical measurement process. This technology helps us to deliver the very best results for clients.

Tool Transfer

If you are looking to change your production to Pre-Met, we have a very fast and efficient tool transfer service.

Contact us to discuss your requirements

Free consultation booking form

We will get back to you as soon as possible

Please try again later

Contact Info

Pre-met Limited

Studley Road, Redditch, Worcestershire, B98 7HJ

T: +44 (0)1527 510 535

Website: www.metalpressingsandstampings.co.uk